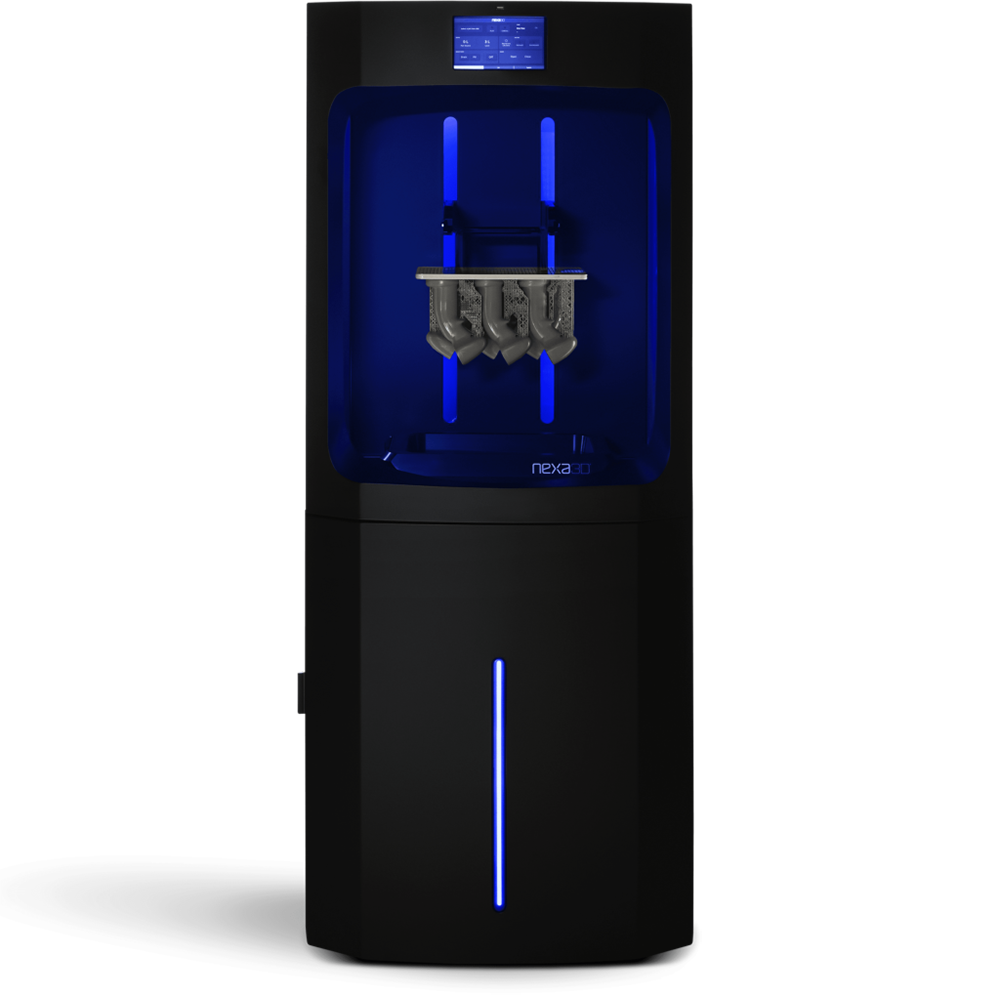

Nexa3D NXE 400 3D Printer

|

||||||||||||||||||||

Call: (888-244-4177) For more information or a sample parts

See what the World’s Fastest Industrial 3D Printer can Do For Your Business

With an unprecedented 16L build volume measuring 10.8 in x 6.3 in x 15.7 in (27.5 cm x 16 cm x 40 cm), intelligent optimization, and Nexa3D’s revolutionary patented LSPc technology, the NXE 400 is the perfect printer for any application.

2.5x Larger Build Volume

The NXE 400 features more than double the build volume compared to currently available technologies, allowing for much larger parts, higher part throughput, and ultimately lower part cost, all with the higher-resolution pixels (75 µm) and isotropic prints.

Manufacturing Ready + Modular Design

In addition to our highly reliable LSPc technology, the NXE 400 is crafted to be completely modular in design for easily interchangeable parts and technology upgrades eliminating hardware obsolescence.

Next-Gen Software + Predictive Service

Nexa3D’s internally developed intelligent software connects our hardware and materials together into a powerful, user friendly system while providing a new era of predictive and prescriptive service. It’s as simple as pressing CRTL+P

Intelligent Part Washer

Improve part quality and reduce labor with the Smart Part Washer to get fully functional parts in minutes with injection molding quality.

Maximize Part Quality and Yield

The NXE 400 is the next scalable manufacturing solution with additional washing and curing units capable of handling even the largest 16L parts on a single tray making the NXE 400 the most advanced printing solution in its class. The washing and curing units are also capable of handling both single large prints and a combination of smaller parts with multiple trays to create finished parts in a matter of minutes in what would normally take hours with today’s available technologies reducing labor costs and post processing times.

Smart and Connected

Our next-generation internally developed software and connected senor system provides intelligent, part-to-part curated washing protocols, part traceability through a digital twin, and automatic software updates to continuously improve the printing experience.