Graphtec CE8000 Series Vinyl Cutter

Product Overview

Boost Your Production Efficiency with the Graphtec CE8000 Vinyl Cutter with ARMS 9

Introducing the NEW Graphtec CE8000 Series, the go-to solution for boosting production efficiency for Signage and Vinyl Graphics, DTF Apparel, PRINT & CUT, POP & Packaging, Automotive Markets, and more.

Compared to its predecessor, the CE7000, the CE8000 boasts Enhanced Rigidity for better feeding and cutting performance. Also equipped with a New Wireless LAN capability, adding convenience and flexibility, allowing seamless connectivity in various work settings. Plus, it's equipped with the reliable Registration Mark Sensing System (ARMS) carried over from the CE7000 for precise operation.

Supercharge your Production Capabilities with the Graphtec CE8000 Series - The Perfect Solution for Streamlined Workflows with Exceptional Results. The CE8000 series, available in models CE8000-40, CE8000-60, and CE8000-130, represents the pinnacle of Graphtec’s cutting technology.

Key Features

- ARMS 9.0 (Advanced Registration Mark System): Delivers unparalleled accuracy in print and cut tasks, ensuring your designs are executed with exact precision.

- Touch Screen & Mechanical Keys: The CE8000's innovative control panel combines a responsive touch screen with traditional mechanical keys, offering users maximum operational flexibility.

- New Menu Structure: A more intuitive and streamlined interface with icon-based navigation makes operation quicker and easier, perfect for both novice and experienced users.

- Integrated Firmware Updates: Stay up to date effortlessly by checking for new firmware through Graphtec Software. Updates can be downloaded and installed via Flash Drive or USB cable.

- Software includes Cutting Master 5 plug-in for Adobe & Corel Users and our popular Graphtec Studio 2 software for design & cut graphics.

- The CE8000 series works with both PC and MAC platforms, or use the USB Thumb Drive Port if needed.

Enhanced Control Panel

- NEW Bladeholder & Mount: The redesigned bladeholder allows for easier tool and blade changes, featuring a sliding stopper for quick adjustments. The tool compartment now has a magnetic base, enabling easy relocation and removal when necessary.

- Wireless LAN: The new wireless LAN connection option provides greater flexibility in installation, allowing the CE8000 to be placed anywhere in your workspace without the limitations of cable length.

- Touch Panel with Mechanical Keys: This dual-input system supports blind touch operation, letting users maintain focus on the media during feeding for faster and more efficient workflows.

Model Improvements: CE7000 vs. CE8000

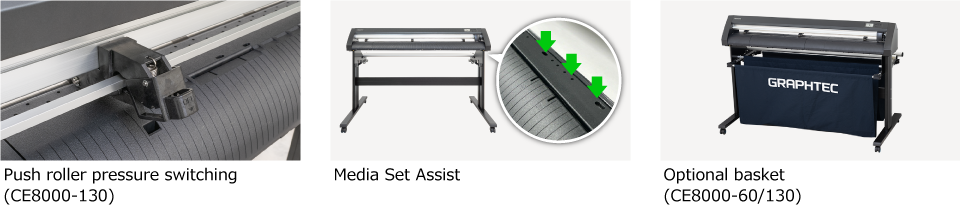

- NEW Push Roller Design: The CE8000-130 features a center push roller that can independently engage or disengage, an upgrade from the three-position pinch rollers on the CE7000-130.

- Revised Accessory Options: The CE8000 has refined its standard accessory package, removing items like the Blade Loupe and Fiber-tip Pen/Holder. These are now available as optional accessories, allowing users to customize their setup.

Additional Features

- Media Basket (Optional): Keep your workspace tidy with the new Media Basket, available as an optional accessory for the CE8000-130 and CE8000-60 models.

- Updated Bladeholder Design: The PHP33-CB09N/15N bladeholders have been redesigned to align with the sleek and modern aesthetics of the CE8000.

- Email Notifications: Stay informed with job completion and error notifications sent directly to your email, ensuring you’re always in the loop.

Advanced Functions

- Wireless LAN: Install your CE8000 cutter anywhere in your office without the constraints of wired connections.

- Media Set Assist: Built-in suction fans help secure the media during feeding, preventing lift and shift for consistent and accurate cuts.

- Fan Media Assist: The CE8000's internal fan activates as sensors detect media, aiding in smooth feeding operations.

Bundle from Big Systems Includes:

- CE8000 E-Class Vinyl Cutter (pick model size 15", 24" or 50")

- Sturdy professional quality stand (stand not available for 15" model CE8000-40)

- Graphtec Studio 2 (Design Software - Windows or Mac OS)

- Cutting Master 5 Plug-In (for Adobe Illustrator on Windows or Mac OS, or CorelDRAW on Windows)

- Windows Driver (for AutoCad or Vector Drawing Software Requiring a Driver)

- Updated Version CB09 Blade Holder for 0.9mm blades

- CB09UB Blade, 0.9mm with 45deg. cutting angle (for a wide variety of cutting applications)

- New and Improved Graphtec ARMS 9 (Advanced Registration Mark Sensing System)

- DataLink Barcode Reading, compatible with any RIP and printer. Also enables cutting from USB drive offline

- Best in Class 450 grams of cutting downforce pressure

- Precision grit-rollers driven by a Digital Servo Motor

- Precise Media Roll Holder for straight media tracking up to 164ft.

- New and Improved Magnetic Cutting Tool and Accessory Holder

- USB Connection for Offline Operation

- Set Up Manual (printed included, online download available)

- Cutting Blade Manual (printed included, online download available)

- 2-Year Parts and Labor Warranty from Graphtec America

- Online Training (Graphtec CE8000 Series Guides & Tutorials)

Graphtec Warranty:

2-Year Parts & Labor Warranty from Graphtec America (with online registration upon purchase and installation).

Shipping and Delivery Requirements:

PLEASE NOTE: The CE8000-60 (24") and CE8000-130 (50") ship in two boxes (cutter and stand). You must be able to receive a small freight shipment (arrives on a small pallet, and weighs up to few hundred pounds. Cannot be shipped to PO Boxes). In most cases, this plotter cutter can be delivered via a lift-gate. However, it's the buyers responsibility to determine if they can receive the shipment via lift-gate before purchase. Buyer assumes all responsibility for delivery and delivery costs, additional services, handling fees, equipment rentals, or any additional costs associated with transport of the cargo (to include re-routing, inside delivery, or returns).

Engineered to Achieve High Performance with Affordable Price

The Graphtec CE8000 Series is the perfect solution for those looking to increase production with greater efficiency for signage graphics, print & cut graphics, pop & packaging, automotive markets and many more. The rigidity has been enhanced compared to the previous model CE7000, which its feeding and cutting quality have also been improved. Wireless LAN has been newly available to enhance the convenience and flexibility. Advanced Registration Mark Sensing System (ARMS) is installed as CE7000.

Top-level Cutting Performance

Pressure adjustable push rollers and newly developed Media Set Assist function help to hold your media stable and prevents from feeding trouble.

By using an optional basket, stability in long roll media cuts can be achieved.

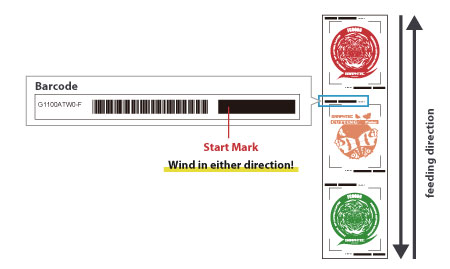

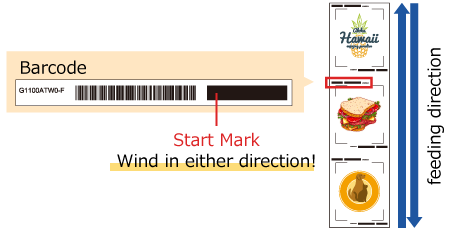

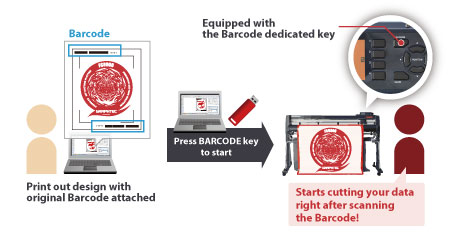

Data Link Function (Barcode Data Management/Continuous Cutting)

By reading the Graphtec original Barcode, CE8000 automatically detects its linked data from PC or USB flash memory. This function is available regardless of which printer or RIP software is used.

- Only FAT32 is supported.

Please note that NTFS and exFAT are not available.

Continuous Cut

Barcode data management allows cutting different data sequentially by detecting the “Start Mark” of the new Barcode. Sequential Print & Cut process with roll-media is now available.

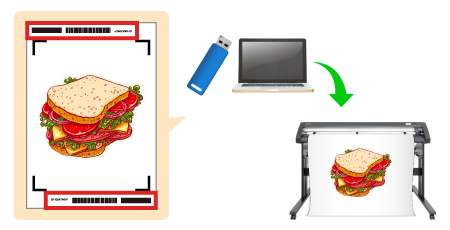

Data output via USB flash memory without PC

When cutting data designed with Cutting Master 5 or Graphtec Studio 2 are saved to USB flash memory, it can be output directly to the cutting plotter by plugging in. This simplified work-flow enables users to operate without a computer.

- Only FAT32 is supported.

Please note that NTFS and exFAT are not available.

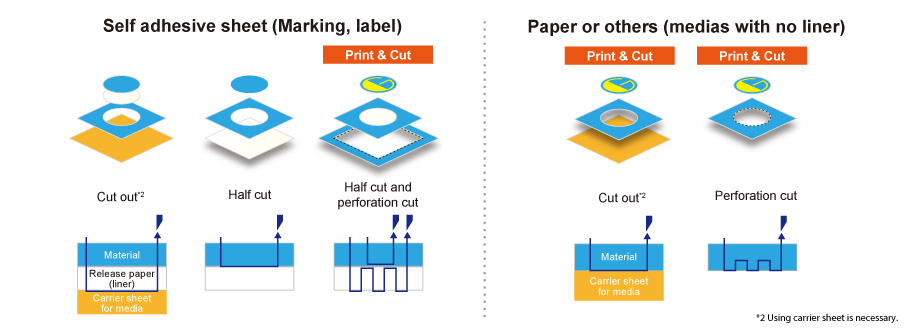

Perforation cutting ability

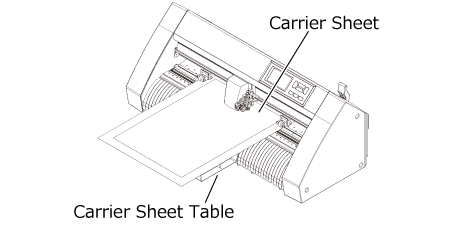

Carrier Sheet Table (OPH-A45)

For cutting sheet media, we line-up the carrier sheet table as an optional item. It is attachable to CE8000-40 / 60.

Software

Standard included software for designing your cutting data and operating cutting plotter.

Cutting Master 5Plug-in software

ARMS (Advanced Registration Mark Sensing system)

ARMS is an abbreviation for Advanced Registration Mark Sensing system, which uses sensors to detect registration marks and performs the AXIS ALIGNMENT. It enables to significantly improve productivity in the Print & Cut applications that makes stickers or decals.

The registration mark is a reference mark for the AXIS ALIGNMENT that makes precisely aligning the actual cutting line with the printed image on media. It is necessary that marks specified by Graphtec are printed on the media to use the ARMS.

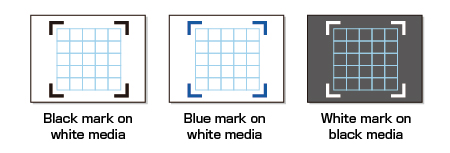

1. Auto sensitivity adjust (Mark may not be detected due to poor printing quality or media surface.)

The sensitivity of the registration mark sensor is automatically set by measuring the reflective level of the marks of the actual media. The mark can be detected when the color of the mark has a reasonable contrast against the background. For example, a white mark can be detected on a colored background.

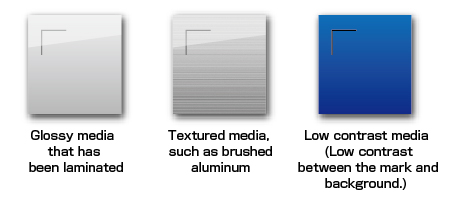

2. ISM (Intelligent Scan Mode) (Mark may not be detected due to poor printing quality or media surface.)

ISM incorporates a new scanning algorithm that expands the range of compatible media. ISM increases the mark scanning success, and can also detect the registration mark on textured media, such as brushed aluminum, or glossy laminated materials.

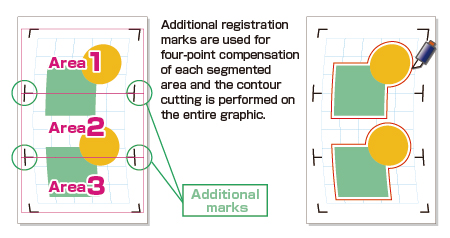

3. Segment area compensation

The 4-point axis alignment is performed for each segmented area. This is performed by reading the mark in the middle of the feeding direction for entire graphic and then cutting the entire graphic, provides high-precision alignment for long length Print & Cut applications. The cutting plotter can be configured to this condition using Graphtec software.

XY segment area compensation is avairable only for FC9000 series.

* The video uses FC9000

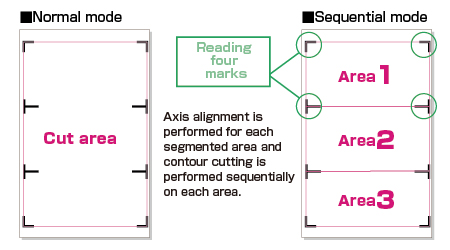

4. Segment area compensation (sequential mode)

The 4-point axis alignment is performed for each segmented area. This is performed by reading the mark in the middle of the feeding direction and then contour cutting is performed sequentially in each segmented area. Media movement is limited to the smaller area being cut, improving accuracy and tracking for heavier media or media that is the entire graphic, provides high-precision alignment for long length Print & Cut applications. The cutting plotter can be configured to this condition using Graphtec software

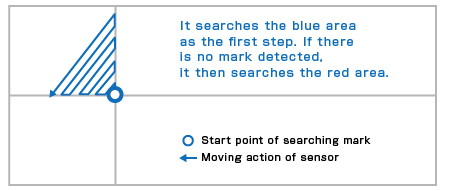

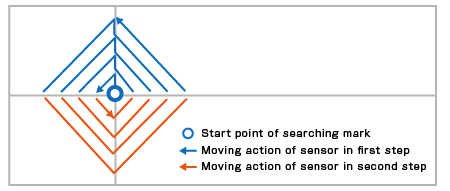

5. Auto mark detection (ver.1)

The first registration mark is automatically detected within search area; this eliminates the need to manually move the sensor near the registration mark position. It improves the operation of the registration mark searching.

6. Auto mark detection (ver.2)

Users do not need to move the sensor manually anymore to find the first mark. Also, the search area has been expanded that the sensor can detect the first mark on minus direction.

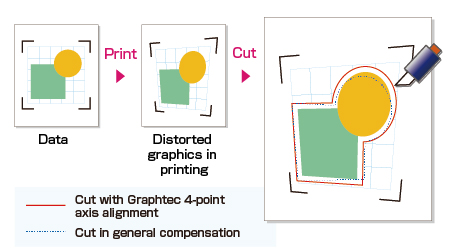

7. 4-point axis alignment

This feature compensates for any distortion in printed graphics to ensure precise contour cutting. The axis alignment using 2-point and 3-point that are faster with limited compensation are also available.

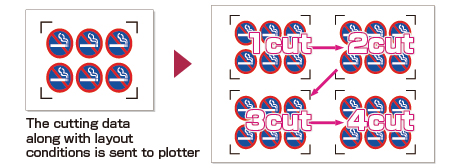

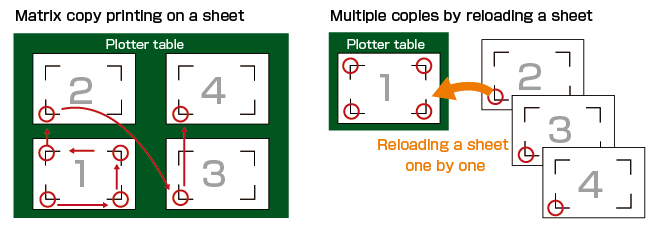

8. Multiple-mark compensation

When the design is printed with the matrix copy condition using RIP software, the action of reading the mark and contour cutting is repeated for each copy. It significantly improve productivity for Print & Cut applications. The cutting plotter can be configured to this condition using Graphtec software.

* The video uses FC9000

9. Supports ARMS control commands

ARMS can be controlled with Graphtec original software. The settings of registration marks are editable via software as well. Also, we provide SDK in response to request from users.

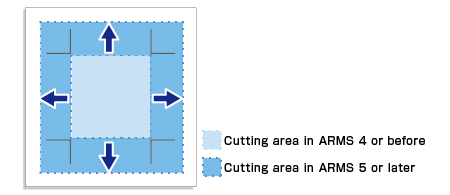

10. Expanded effective cutting area

In case of ARMS 4 or before, the cutting area is up to the area enclosed by the registration mark. In case of ARMS 5 or later, the cutting area is expanded to outside of the area enclosed by the registration mark. This increases the production efficiency by reducing media waste.

* The video uses FC9000

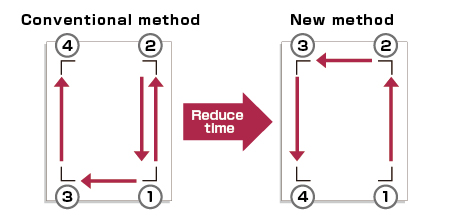

11. Reduce mark detection time

Sequence of scanning the mark is changed for significantly reducing the mark detection time. This function is available in ARMS 5.0 or later.

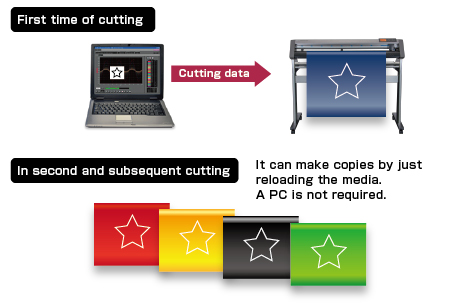

12. ARMS Copy

After data is sent the first time, it can be copied multiple times without a PC. It enables to improve the work efficiency of Print & Cut applications.

13. Axis alignment by the first mark

After data is sent the first time, it can be copied multiple times without a PC.

In case of ARMS 6.0 that is available on FCX2000 / FCX4000, the first four marks are scanned on the first sheet, and only the first mark in subsequent sheets. This improves productivity by shortening scan detection time. The cutting plotter can be configured to this condition using Graphtec software.

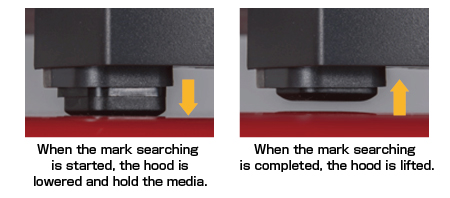

14. Hood of sensor (media holder)

The hood incorporates to the mark sensor part. It has a function of holding the media to the panel for preventing the lifting of the media. It also prevents the influence of ambient light. It can read the mark in stable.

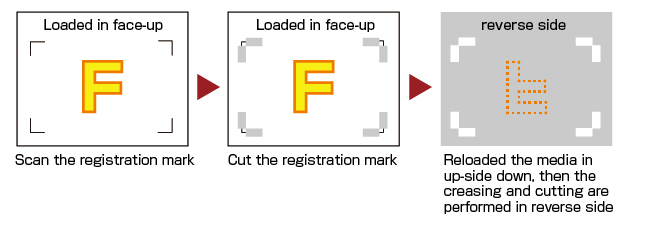

15. Reverse side processing

Cutting and creasing of printed graphics is possible even on the reverse side of the media. This prevents any scratches or damage to the printed graphic. In case of ARMS 6.0 that is available on FCX2000 / FCX4000, operation is very simple when Graphtec software is used.

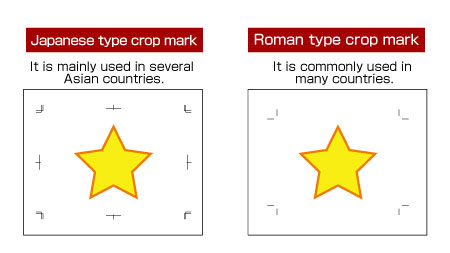

16. Supported the standard crop marks

The axis alignment can be performed using by printed industry standard crop mark for shear. Adding special marks with Graphtec software is not necessary. The Japanese type is supported on the FC2250 series, FCX2000 series and FCX4000 series. The FCX2000 / FCX4000 supports also the Roman type. In case of ARMS 6.0 that is available on FCX2000 / FCX4000, operation is very simple when crop mark information is entered within Cutting Master 4 software when it is used with Adobe Illustrator.

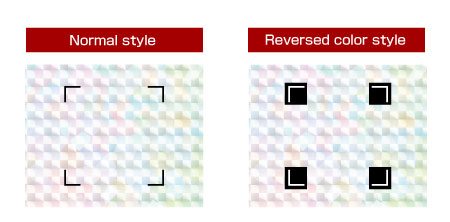

17. Supported reversed color mark

The sensitivity of the registration mark sensor is automatically set by measuring the reflective level of the actual media. The mark can be detected when the color of mark has a reasonable contrast against the background. For example, the mark can be detected with a white mark on a colored background, on a textured media such as brushed aluminum, or on a glossy laminated media.In case of using the Graphtec software, reversed color mark can be easily created.

18. Supports colored marks / specialty media

A wide variety of media types including holographic paper and reflective sheets are now compatible due to improvements of the ARMS sensor algorithm.

- Sensor may not be able to read certain combinations of specialty media and colored marks.

19. Data Link Function (Barcode Data Management/Continuous Cutting)

By reading the Graphtec original Barcode, FC9000/CE8000/CE7000 automatically detects its linked data from PC or USB flash memory. This function is available regardless of which printer or RIP software is used.

- The USB flash memory format only supports FAT32. Please note that NTFS and exFAT are not supported.

20. Continuous Cut (Data Link function)

Barcode data management allows cutting different data sequentially by detecting the “Start Mark” of the new Barcode. Sequential Print & Cut process with roll-media is now available.

* The video uses FC9000