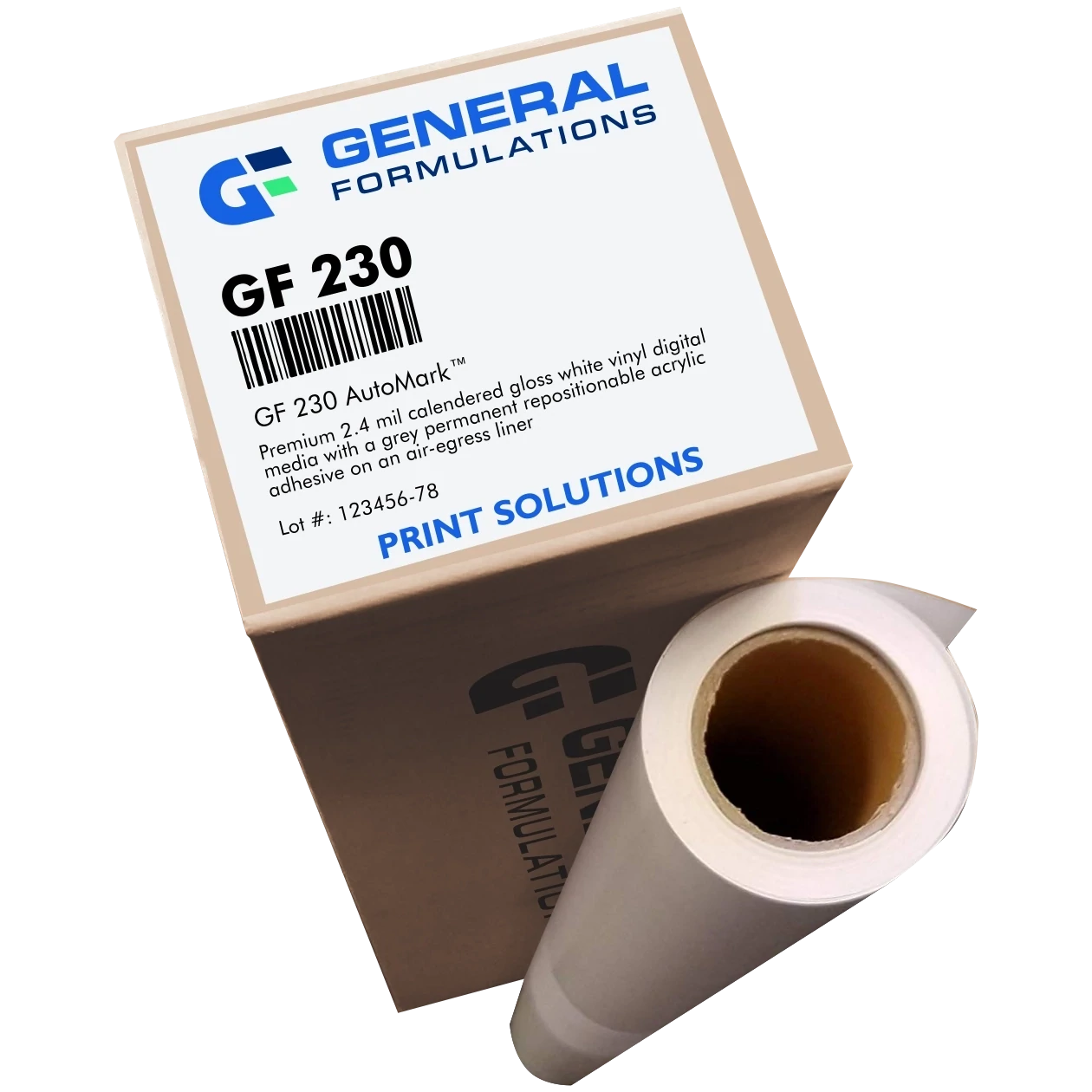

General Formulations 230 AutoMark™ Gloss White Vinyl - Permanent Air-Egress

GF 230 is a Premium 2.4 mil calendered Gloss white vinyl digital media with a grey permanent repositionable acrylic adhesive on an air-egress liner. This film is designed to accept a variety of solvent, latex and UV curable inks common to wide format digital printing systems. The grey permanent adhesive offers excellent opacity and exceptional repositionable qualities. GF 230 AutoMark™ Premium 2.4 mil calendered gloss white vinyl digital media is specifically engineered for use in most vehicle wrap and decal applications. The 90# Air Egress Layflat liner allows for good lay-flat and air-free application

Is AutoMark a full wrap film?

AutoMark™ works best with simple to moderate curves. It is a polymeric calendared vinyl, and thus is not meant for complex curves. A cast film may be better suited for vehicles with complex curves and deep recesses.

What types of vehicles are ideal for GF 230 AutoMark™?

GF 230 Premium 2.4 mil Calendared gloss white vinyl digital media is designed to be applied to corrugations, riveted surfaces, flat and slight to moderate curves. The construction can be used on vans, trucks, sedans of all sizes, fleet and recreational vehicles.

What are the recommended laminates for GF 230?

Our standard laminates are GF 231 UV Gloss and GF 240 UV Matte finishes. For a higher gloss finish use GF 242 UV Gloss Cast laminate.

Can I use wet application techniques on the GF 230?

No. Although AutoMark™ has a solvent based adhesive, the air-egress technology could potential trap fluids and be extremely difficult to extract and remove. Wet application is not warranted.

Can I use primer with this product?

We do not recommend Primer 94 with our product. If absolutely necessary a small amount of Pro Bond™ Adhesive Promoter may be used in the tougher areas, but best practices are to clean the surface and crevases thoroughly, as most failures are the result of dirt and debris.