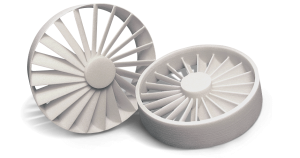

High-Quality Prototype Service From Your Design Files

Rapid prototyping is ideal for fast design iterations and part testing. Our expertise and capabilities allow for a variety of material options and ensure a consistently high level of quality while maintaining quick turnaround times. Our on-demand service will bring your prototypes to life and create real functional end-use parts.

Enter your information below, and provide the details and any additional information regarding your project. Submit the STL, STP, SLDPRT or STEP files. Choose the desired materials below. You will receive a quote, and confirm your order.

Maximum upload size is 40meg. When sending multiple files, please place them in a zip file.

3D RapidParts | |||

| First Name | Last Name | ||

| Company | |||

| Phone | |||

| Address | City | ||

| State | Zip | ||

| Technology | Notes: | ||

| Upload File | |||

The Send File & Data button will become active after all fields are filled in.

Best = ••••• Better = •••• Good = •••

Markforged MJP SLA #1 SLA #2 SLS DMP | ||||||

| MarkForged | Tough Nylon | Onyx | Carbon CFF | Kevlar CFF | Fiberglass CFF | HSHT Glass CFF |

| Tensile Modulus ASTM D638 | | | ||||

| Tensile Stress at Yield ASTM D638 | | | ||||

| Tensile Strain at Yield ASTM D638 | | | ||||

| Tensile Stress at Break ASTM D638 | | | ||||

| Tensile Strain at Break ASTM D638 | | | ||||

| Tensile Strength ASTM D3039 | | | | | ||

| Tensile Modulus ASTM D3039 | | | | | ||

| Tensile Strain at Break ASTM D3039 | | | | | ||

| Flexural Strength ASTM D790 | | | | | | |

| Flexural Modulus ASTM D790 | | | | | | |

| Flexural Strain at Break ASTM D790 | | | | | | |

| Compression Strength ASTM D6441 | | | | | ||

| Compression Modulus ASTM D6441 | | | | | ||

| Compression Strain at Break ASTM D6441 | | | | | ||

| Heat Deflection ASTM D648 | | | | | | |

| Izod Impact notched ASTM D256-10 | | | | | | |

Markforged MJP SLA #1 SLA #2 SLS DMP | ||||||

| MJP | VisiJet M3 Hi-Cast | VisiJet M2R-WT | ||||

| Color | | | ||||

| Density @ 20 °C (solid) ASTM D792 | | |||||

| Density @ 80 °C (liquid) ASTM D3505 | | |||||

| Tensile Strength ASTM D638 | | |||||

| Tensile Modulus ASTM D638 | | |||||

| Elongation at Break ASTM D638 | | |||||

| Flexural Strength ASTM D790 | | |||||

| Flexural Modulus ASTM D790 | | |||||

| Impact Strength (Notched Izod) ASTM D256 | | |||||

| Shore D Hardness ASTM 2240 | | |||||

| Water Absorption ASTM D570 24 hr | | |||||

| Heat Distortion Temp @ 0.45 MPa ASTM D648 | | |||||

| Heat Distortion Temp @ 1.82 MPa ASTM D648 | | |||||

| Melting Point | | |||||

| Softening Point | | |||||

| Volumetric Shrinkage from 40 °C to RT | | |||||

| Linear Shrinkage from 40 °C to RT | | |||||

| Needle Penetration Hardness ASTM D1321 | | |||||

| Ash Content ASTM 2584 | | |||||

Markforged MJP SLA #1 SLA #2 SLS DMP | ||||||

| SLA #1 | Accura 25 | Accura Xtreme 200 | Accura Xtreme Grey | Accura 55 | Accura SL 7810 | Accura SL 7820 |

| Class | | | | | | |

| Accuracy | | | | | | |

| HiTemp | ||||||

| Moisture Resistance | | | | | | |

| Optical Clarity | ||||||

| Durability | | | | | | |

| Color | | | | | | |

| Investment Casting | ||||||

| Master Patterns | | | | | | |

| Snap Fit Assemblies | | | | | | |

| General Purpose Models | | | | | | |

| Automotive | ||||||

| Wind Tunnel | ||||||

| Viscosity (cps) (@30°C) | | | | | | |

| Flexural Modulus (MPa) ASTM D 790 | | | | | | |

| Flexural Strength (MPa) ASTM D 790 | | | | | | |

| Tensile Modulus (MPa) ASTM D638 | | | | | | |

| Tensile Strength (MPa) ASTM D 638 | | | | | | |

| Elongation at Break ASTM D 638 | | | | | | |

| Impact Strength (J/m) ASTM D 256 | | | | | | |

| Heat Defl. Temp (°C) ASTM D 648 | @66 PSI - 58-36 @264 PSI - 51-55 | @66 PSI - 47 @264 PSI - 42 | @66 PSI - 62 @264 PSI - 54 | @66 PSI -55-58 @264 PSI - 51-53 | @66 PSI - 51 | @66 PSI - 51 |

Markforged MJP SLA #1 SLA #2 SLS DMP | ||||||

| SLA #2 | Accura Clearvue | Accura 60 | Accura Cast Pro | Accura Bluestone | Accura 48 HTR | Visijet SL Clear |

| Class | | | | | | |

| Accuracy | | | | | ||

| HiTemp | | | ||||

| Moisture Resistance | | | | | | |

| Optical Clarity | | | ||||

| Durability | | | ||||

| Color | | | | | | |

| Investment Casting | | | ||||

| Master Patterns | | | ||||

| Snap Fit Assemblies | | | ||||

| General Purpose Models | | | ||||

| Automotive | | |||||

| Wind Tunnel | | |||||

| Viscosity (cps) (@30°C) | | | | | | |

| Flexural Modulus (MPa) ASTM D 790 | | | | | | |

| Flexural Strength (MPa) ASTM D 790 | | | | | | |

| Tensile Modulus (MPa) ASTM D638 | | | | | | |

| Tensile Strength (MPa) ASTM D 638 | | | | | | |

| Elongation at Break ASTM D 638 | | | | | | |

| Impact Strength (J/m) ASTM D 256 | | | | | | |

| Heat Defl. Temp (°C) ASTM D 648 | @66 PSI - 58-36 @264 PSI - 51-55 | @66 PSI - 47 @264 PSI - 42 | @66 PSI - 62 @264 PSI - 54 | @66 PSI -55-58 @264 PSI - 51-53 | @66 PSI - 51 | |

Markforged MJP SLA #1 SLA #2 SLS DMP | ||||||

| SLS | DuraForm PA | DuraForm GF | DuraForm EX White | DuraForm EX Black | DuraForm HST | |

| Flexible/durable | | | ||||

| Non-rigid/durable tough | | | | |||

| High Temp resistance | | | | | | |

| High elongation | | | | |||

| High-impact strength | | | | | | |

| Accuracy | | | | | | |

| Surface finish | | | | | | |

| Color | | | | | | |

| Production parts | | | | | | |

| Parts w/snap fits | | | | |||

| Automotive design | | | | | | |

| Aerospace parts | | | | | | |

| Medical applications | | |||||

| Jigs/fixtures/tools | | | | | | |

| Density sintered part ASTM 792 | | | | | | |

| Flexural Modulus (MPa) ASTM D 790 | | | | | | |

| Flexural Strength (MPa) ASTM D 790 | | | | | | |

| Tensile Modulus (MPa) ASTM D638 | | | | | ||

| Tensile Strength (MPa) ASTM D 638 | | | | | | |

| Elongation at Break ASTM D 638 | | | | | | |

| Impact Strength (J/m) ASTM D 256 Notched Izod, 23°C Unnotched Izod, 23°C | 32 336 | 41 123 | 74 1486 | 74 1486 | 37.4 310 | |

| Heat Defl. Temp (°C) ASTM D 648 @0.45MPa @1.82 MPa | 180° C 95° C | 179° C 134° C | 188° C 48° C | 188° C 48° C | 184° C 179° C | |

| Flammability UL 94 | | | | | | |

| Hardness ASTM D2240 | | | | | | |

Markforged MJP SLA #1 SLA #2 SLS DMP | ||||||

| DMP | Stainless 316L | Titanium | Aluminum Alloy ALSi12 | |||

| Chemical Composition | ||||||

| | | | ||||

| | | | ||||

| | | |||||

| | | | ||||

| | | |||||

| | | |||||

| | | |||||

| | | | ||||

| | | |||||

| | | |||||

| | | |||||

| | | |||||

| | | | ||||

| | | |||||

| | | |||||

| | | |||||

| | | |||||

| | | | ||||

| Ultimate Tensile Strength ASTM E8 As-built After post heat treatment | 480 MPa ± 20 240 MPa ± 20 | |||||

| Yield Strength ASTM E8 As-built After post heat treatment | 270 MPa ± 20 180 MPa ± 20 | |||||

| Elongation at Break ASTM E8 As-built After post heat treatment | 5.5% ± 1.0 20% ± 4.0 | |||||

| Hardness As-built After post heat treatment | 137 ± 1.5 HB 90 - 95 HB | |||||

| Density | | |||||

| Youngs Modulus ASTM E8M | | | ||||

| Yield Strength (Rp 0.2 %) ASTM E8M | 1100 MPa ± 100 MP | 470 MPa ± 70 MP | ||||

| Ultimate Tensile Strength ASTM E8M | 1190 MPa ± 100 MPa | 600 MPa ± 100 MPa | ||||

| Elongation at Break ASTM E8M | 8% ± 2% | 40% ± 20% | ||||

If you have any questions, or need to talk with one of our 3D parts specialists, just give us a call.