Expanding into high-value applications allows you to stay ahead in the printing world. That means investing in new technology and innovation, such as the ability to print on both rigid and flexible substrates with water-based inks. HP’s revolutionary Latex R Printer series offers your customers the ability to showcase their products or services in unique and inventive ways with the glossiest white ink and the most vibrant colors on rigid substrates. HP Latex combines more advantages into one technology than any competitive alternative and offers improved productivity performance and access to new applications like short-run special packaging or printed thermoforming.

Across industries, demand for thermoformed printing services is rapidly growing. Yet, many print businesses are unsure how to expand into this lucrative area. Let’s explore how you can produce thermoformed prints with rich colors designed to resist color density loss when stretched into deep-draw forms with the HP Latex R Printer series.

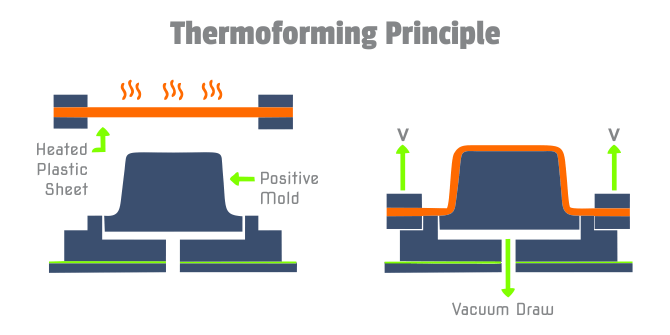

What is Thermoforming?

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The sheet, or “film” when referring to thinner gauges and certain material types, is heated in an oven to a high-enough temperature that permits it to be stretched into or onto a mold and cooled to a finished shape. Its simplified version is called vacuum forming.

Thermoforming Barriers & Challenges

- Most outdoor signage is decorated with cut vinyl and applied to a formed shape – then the sign is often stenciled and/or painted, especially for the diffuser. Heavy cost and labor.

- Solvent and Eco-solvent inks do not provide the density required and need to be printed to SAV and applied to substrate

- UV inks crack and do not have elongation capabilities; UV printer manufacturers offer a special ink set for thermoforming which requires a change-over

- Limited gamuts and density of digital inks make color matching very difficult as well as opacity especially for backlighted images

- Many PSPs do not understand the process, so thermoformers do not feel outsourcing the printing is viable

How HP Latex Offers a Bright Spot to Thermoformers

- HP Latex ink is very robust – it can be heated well over 400° F and elongates (draws) to over 7-8 inches comfortably

- Adhesion to polycarbonate, PET, polystyrene and acrylics is outstanding. Excellent compatibility with third party coatings

- HP Latex 882 (color) inks provide extended gamut and MR4 firmware supports print modes and ink densities up to 390% printing. The HP Latex 886 (white) is superior to UV inks and offers several solid choice points regarding translucent options (backlighting)

- Image quality (IQ) drives higher value opportunities for customers

- Digital printing offers a more efficient workflow – simplified printing process, reduced labor and elimination of trial-and-error iterations

Expanding Into High-Value Applications

Key Features

Sometimes you want one printer that can do it all. Today that printer exists, and it’s called the HP Latex R Printer series.

- Get amazing colors, rigid and flexible up to 98 inches

- Grow your business into higher value rigid/flexible jobs with vibrant HP Latex gamut media look and feel.

- Gain versatility with HP Latex Ink—from indoor/outdoor signage to thermoforming and high-quality decoration.

- Win more jobs with UL ECOLOGO® Certified, waterbased HP Latex Inks that produce odorless prints.

HP has removed the barriers to print with white

- Expand your portfolio into a wide range of applications with glossiest white that resists yellowing.

- No waste between white jobs4 with removable HP Thermal Inkjet printheads stored in offline rotating chamber.

- You’re always ready to print white—automatic recirculation and printhead cleaning eliminate manual purging.

Manage Your Peaks In-House with Smart Printing

- Meet production peaks—get high-speed quality up to 15 outdoor boards/hr5 with belt system, smart vacuum.

- Help avoid costly operating errors with an easy interface including advanced queuing and multiboard printing.

- Maximize uptime with automatic maintenance and smart service tools for fast diagnosis and issue resolution.

- Maintain control of your production and costs with the help of HP PrintOS software tools.

Outstanding Benefits of HP Latex White Ink

HP’s white ink solution has an innovative system that recirculates the white ink – both within the ink delivery system and at the printhead. Removable HP Thermal Inkjet printheads are stored in the offline rotating chamber, for no clogs and no waste between jobs.

The glossiest of whites

Our white ink lays smooth, even, and flat so it takes on the shape of the media. It reflects light directly and uniformly, for a high gloss consistency. UV-curable ink lays unevenly, hides media texture, and can reduce gloss and color.

Resists yellowing over time

Our white ink is highly resistant to photochemical reactions and doesn't contain photoinitiators or optical brighteners, unlike UV-curable inks.

High Opacity

Our white ink achieves a very opaque, visually strong white by using exterior grade titanium dioxide pigments that are three times the size of the colored ink particles and twice the volume.

Expanding into High-Value Applications

With HP Latex R Printer series, you can give your point of sales applications an extra dimension with thermoformed prints, amazing colors, and the glossiest of whites.1 Achieve the same look across rigid and flexible campaigns using one technology and say goodbye to print and mount. Thermoformed prints are designed to resist color density loss.

There is increasing demand for customized and digitally printed applications. Latex Inks bring considerable advantages to printed thermoforming applications due to its flexibility and temperature resistance. It can provide thermoformed prints with rich, deep colors that don’t fade when stretched into deep-draw forms. A wide range of substrate can be used in thermoforming, and the end product can range from prototypes, point of sale material, and blister packs to industrial parts.

Expanding Into High-Value Applications: Indoor POP & backlit gaming

Create brilliant POP displays and backlit gaming consoles that are capable of grabbing customers’ attention with rich, vibrant colors, high-opacity white2, and eye-catching detail.

Expanding Into High-Value Applications: Outdoor signage

Create stunning large signs with deep draw designed to resist color density loss due to stretching of the media, and high-opacity white2 for backlit signs.

Expanding Into High-Value Applications: Plastics manufacturing

Create high-quality plastic manufacturing and a deep draw, with reduced iterations. Flexible HP Latex Inks resist color density loss and are designed to better resist cracking during production, and chipping during finishing, compared to UV ink based technologies.

To learn more, visit the Latex R-Series portfolio at: https://bigsys.com/wp/Store.php#!/Flatbed-Printers/c/117034786

1 Most vibrant colors based on internal HP testing, January 2018 compared to leading competitive printers under $350,000 USD. Tested in High Quality print mode on rigid (white acrylic 12-pass, 6-color, 120%). Internal HP testing with HP GamutViewer, Alpha Shapes=50000.

2 Glossiest white based on internal HP testing in January, 2018 compared to the HP Scitex FB750/FB550 Printer using UV-curable ink technology. White ink measured for the level of gloss at 60 degrees on a rigid material (acrylic). Tested using Glossmeter BYK micro-TRI-gloss (20°, 60°, 85°), compatible with ISO 2813 and ASTM D523 relative to glossiness measure. High opacity and resists yellowing over time based on internal HP WeatherOmeter testing October, 2017 with 1 dot-per-pixel HP Latex Overcoat, on a range of rigid and flexible unlaminated substrates. Yellowing based on L* and B* of white underflood samples. White ink capability may be optional, requiring purchase of the HP White Ink Option Kit.

3 HP Latex Inks are UL ECOLOGO® Certified. UL ECOLOGO® Certification to UL 2801 demonstrates that an ink meets a range of multi-attribute, lifecycle based criteria related to human health and environmental considerations (see http://www.ul.com/EL). There is a broad set of media with very different odor profiles. Some of the media can affect the odor performance of the final print.

4 When HP 886 White Latex Printheads are placed in the storage cassettes, no white ink is used for servicing when printheads are not in use.

5 Outdoor mode 3-pass, 70%. On 4 x 8 ft (1.2 x 2.4 m) boards.